Project Overview

AICA, in collaboration with a channel partner, embarked on a journey to revolutionise data management for a mining operation in the United States. Utilising our state-of-the-art AI-driven SaaS platform, our goal was to tackle substantial data quality challenges and unlock new avenues for cost savings and operational efficiency.

Client's Challenge

Following the migration from Sage to SAP, our client faced significant data management challenges, such as:

- \Missing Data (costing, materials, and values)

- \Inaccurate Data (total value of stock)

- \Non-Standardised Data (poor quality raw data)

The primary objective was to enhance data quality and insource mining activities, thereby improving decision-making and operational efficiency.

Solution

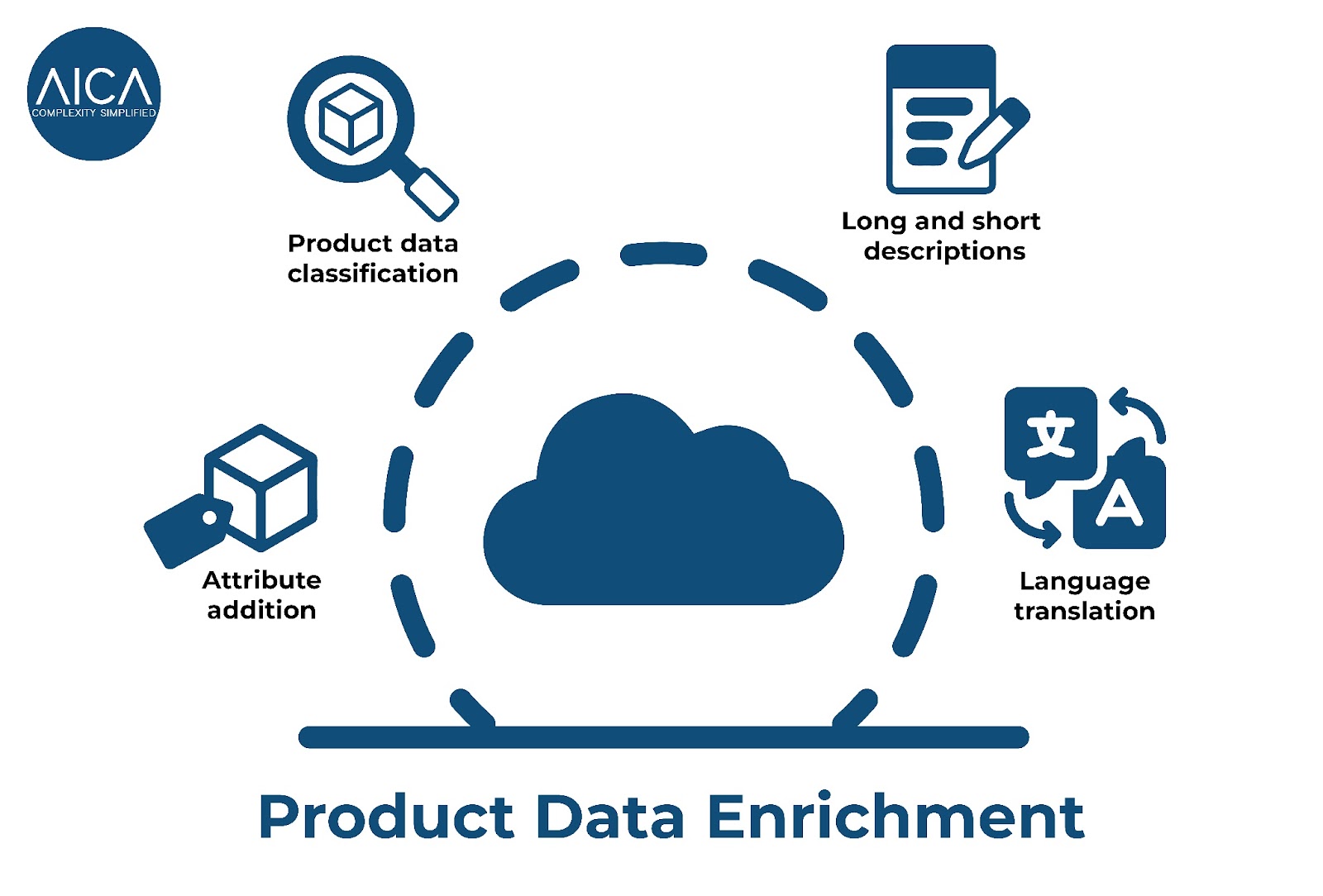

AICA, specialising in product data cleansing, enrichment, creation and comparison, was deployed to meet these challenges. Our methodology included:

- \Preparing and training a large language model

- \Processing and analysing the data

- \Providing analytical support

- \Interpreting the results

SCM Efficiency Improvements and Client ROI

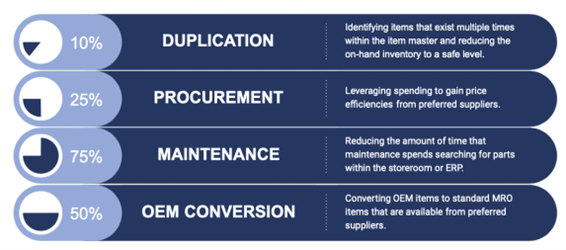

We’ve developed a cost savings model based on our data cleansing and enrichment solution. The ROI Model uses the client’s baseline data and applies standard cost-saving metrics. The model’s outputs indicate dollar and percentage savings in key areas such as duplication, procurement, maintenance, and OEM conversion.

Preliminary Cost Savings Estimates:

- Procurement: Savings up to 25%, with deduplication being a critical component.

- Maintenance: Savings around 75%, with improved data descriptions impacting plant performance.

- OEM Conversion: Savings up to 50%, particularly for rubber and hose products.

Results and Impact

- REnhanced operational visibility and SCM performance

- RImproved decision-making processes

- RTangible cost savings and data management improvements

Data Integration and Improvement

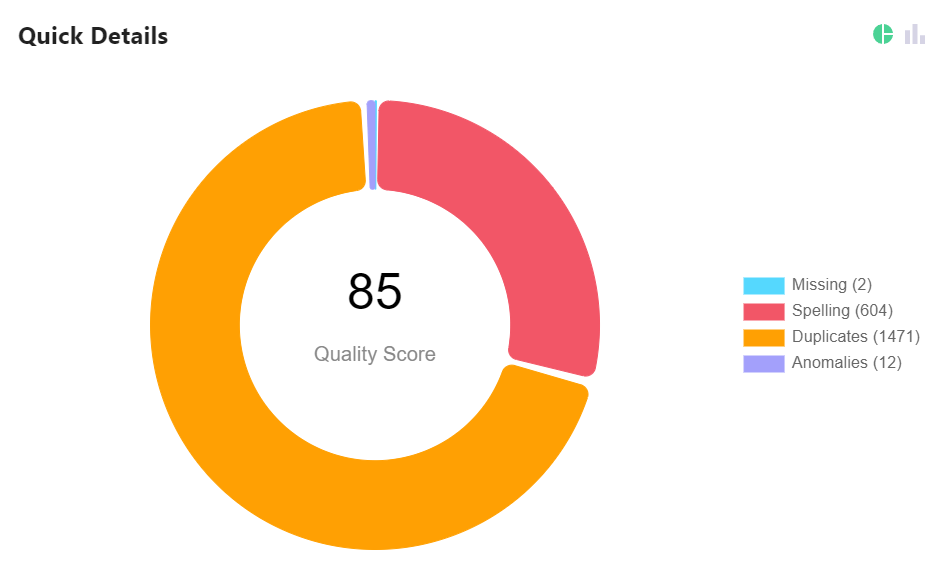

Our initial analysis indicated that approximately 8,500 items in the client’s material catalogue were processed. Over 58% of the data was analysed using our proprietary AICA model, which led to the identification of critical discrepancies.

For example, it was noted that about 2,600 items were not transferred during the system migration, and duplicate items representing a potential impact of roughly $3 million were identified. These findings are vital for the next phase of the project.

Data Cleansing and Enrichment

Challenges and Solutions

The raw data provided by the Client presented initial obstacles due to its format and quality, rendering it incompatible with the standard data cleansing procedures of the AICA solution. However, this hurdle was navigated by pivoting to a robust product data enrichment process. This alternative strategy not only elevated the data’s utility but also addressed cleansing concerns indirectly by correcting spelling errors and rectifying anomalies.

In evaluating the data, it was critical to discern the nature of duplicate entries. Duplicates might typically signify an error within the dataset. Yet, they can also reflect a deliberate strategy of item allocation across various warehouses or locations, particularly in a distributed inventory system. Such was the consideration when examining the identified duplicates in the Client’s dataset.

Advancements through Data Enrichment

The transformative impact on the Client’s dataset was most evident in the realm of product data enrichment. The enhancement process went beyond mere correction, venturing into the domain of classification—the intricate task of systematically organising product data by their defining features and characteristics. This level of organisation is instrumental for businesses in delivering precise and beneficial information to customers.

Our algorithms played a pivotal role in this stage, adeptly pinpointing and supplementing missing elements within the product data. The completion and refinement of this information not only bolster the integrity of the dataset but also unravel insights into customer trends and preferences.

Classification

The enrichment process meticulously outlined the following key informational classifications:

- UProduct Segment

- Family

- Class

- Commodity

Despite the advancements, the enrichment process encountered a gap in the business function information. This specific aspect could not be populated until additional relevant data is provided by the Client.

The enriched data output notably encompasses essential fields such as:

- \Product Attributes (11 fields)

- \UNSPSC Classification

- \Short Description

- \Long Description

Streamlining New Stock Entries (ANSI)

Maintaining the integrity of a cleansed and enriched dataset necessitates stringent protocols for the entry of new stock items. These new entries must align with the structured framework of the Material Catalog File. To this end, the Client is tasked with the implementation of an effective ANSI process that dovetails with the enriched dataset.

AICA’s comprehensive implementation procedure assimilates ANSI within its data cleansing and enrichment services, establishing it as a cornerstone of master data management.

Future Roadmap

Our next steps include subscribing to our SaaS platform, conducting thorough data analysis, completing SAP setup, AICA installation, SCM analysis and ensuring data consistency across operations.

Conclusion

AICA represents a transformative approach to product data management in mining. With further implementation, we aim to deliver a comprehensive solution that promises not only refinement but a revolution in the product data management landscape.

We specialise in product data & services cleansing, enrichment, and comparison utilising AI and ML to detect a wide array of errors and inconsistencies in your data.

Ensuring that your data works for you. Feeding your Master Data Management system with pristine and enriched data.